Getting Started 3D Printing

I've gotten several questions about my 3D printer and how to get started 3D printing in general- so I figured I'd write up what I've found in my research and experiences. Your mileage may vary.

3D printing is exciting and the possibilities are endless. It seems like every day the printers and getting cheaper and the variety in designs and possibilities for using them are growing and getting better. It's becoming more and more accessible even to those casually interested. This means prices are coming down for a lot of the parts.

First, there are two main camps: open designs and commercial models. There are quite a few open models and quite a few commercial ones. I'll provide some sweeping generalizations on these two camps from what I've seen.

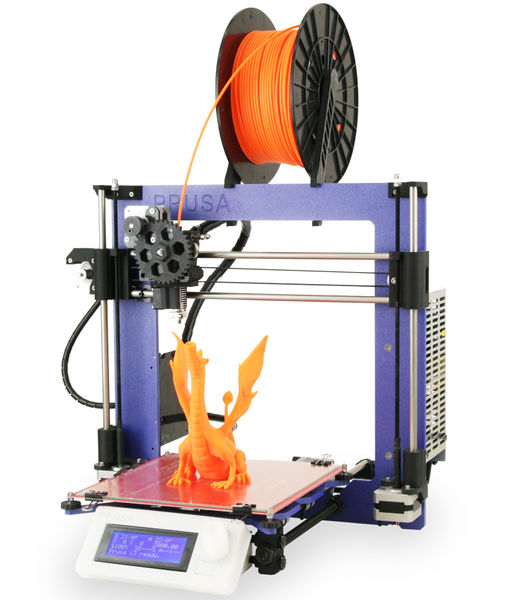

Open Design Printers

The open design printers are generally geared toward the hobby enthusiast and most of them cater to trying to be made of off-the-shelf parts. These tend to require a lot of hands-on tweaking and learning to actually get a first good print. In addition, they are usually easy to customize. The options for software bring a lot of variety, some better than others, but I have absolutely no complaints with the software stack I currently use. Open printers also generally allow a much bigger variety of print material. This is both good and bad. You can source cheap print material and you can get it in a variety of properties, but it tends to be more trial and error to get good prints with it. For example, having a very consistent diameter on the whole spool of plastic is important so the printer can accurately control the amount of material pushed through the extruder.

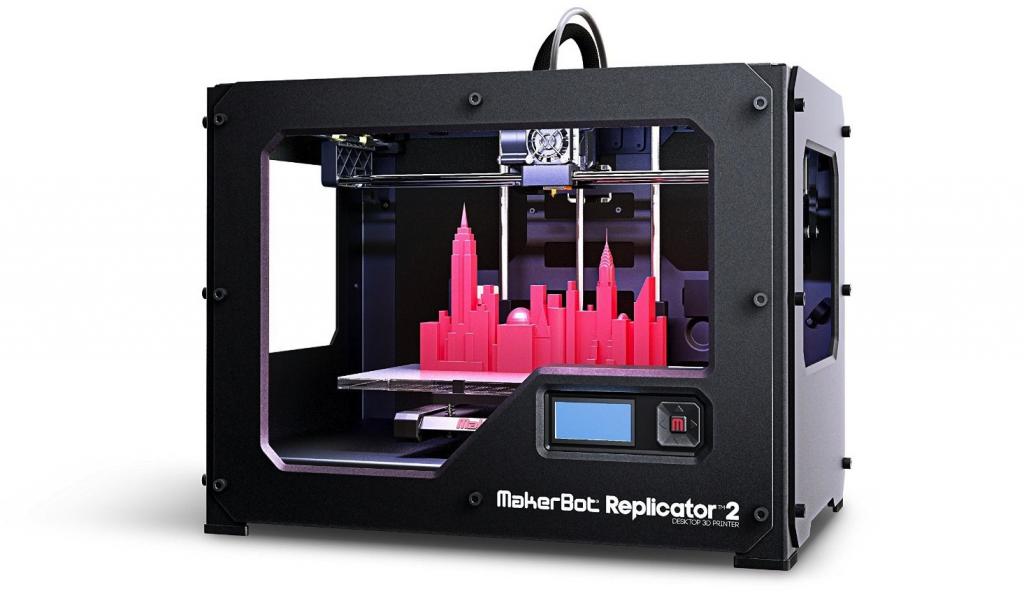

Commercial Printers

The commercial printers attempt to be more plug and play, but usually start at far more than the cheapest open design printer. The support and software may end up being better for your specific printer, but it's going to limit your options and usually be closed source. Also, you'll want to be cautious of your options for print material. A lot of the commercial printers attempt to make you buy print material from them. The plus side of this is it's going to work as expected with little tweaking.

Different Types of Plastic

There are two main types of plastic print material: ABS and PLA. Other materials like nylon are gaining, but I don't have any direct experience with them. I currently use ABS, but each print material has its own drawbacks and pluses. PLA tends to be a bit more brittle and less forgiving. ABS bends and is somewhat flexible. ABS and PLA come in two main diameters. 3mm and 1.75mm seem to both be used almost equally and one really offers no benefit over the other. I can say this because I have yet to notice a major price difference. Keep in mind though that your extruder will take a specific diameter.

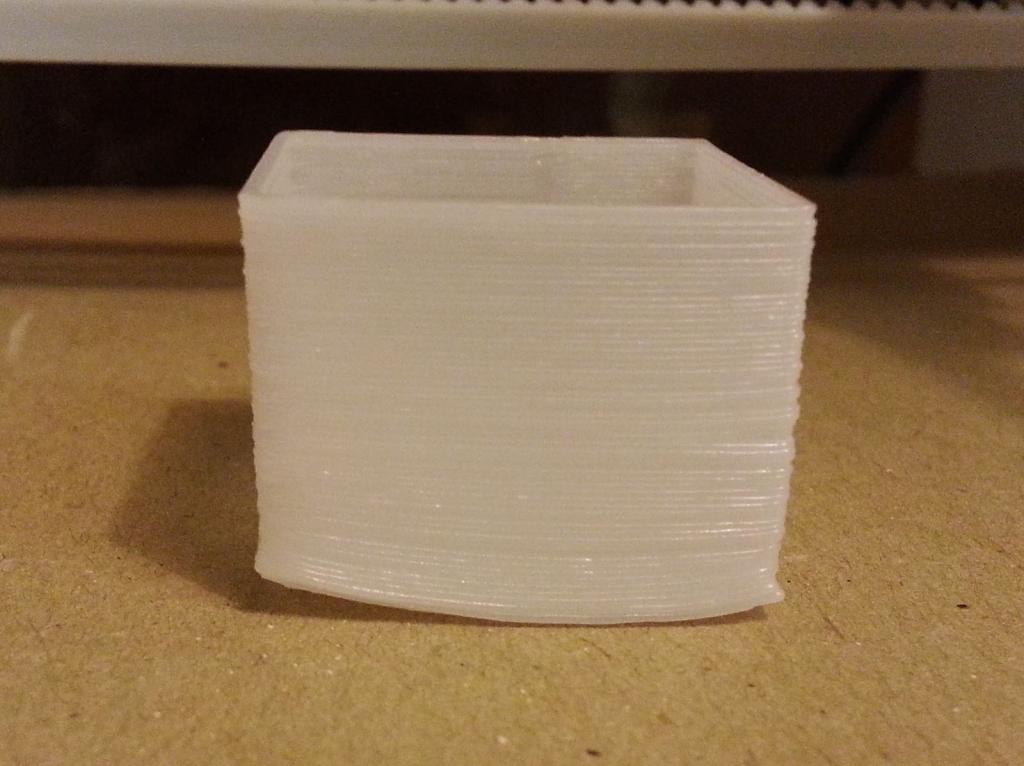

Pay attention to the print area size. Try to envision how big some things you want to print are and make sure your printer can print those. However, this is a double edged sword. Plastic warps as it cools, so the larger the print the bigger this is going to play a factor. Also, the larger the print, the longer the print time. Generally speaking, don't expect large objects to be easy to print.

Things to Keep In Mind

Here are some things to keep in mind when looking for and getting started with 3D printing.

Warping

ABS warps. If you use ABS, you will fight this. I have yet to find a perfect solution and it ultimately depends on the model and what day of year it is, or so it seems. I've used different tapes on the heat bed. I've played with heat-bed temperatures. I've dang near built walls around the print to restrict airflow on a printer where the heat bed itself moves. I've used hairspray on the heat bed. In the end, what I use most often is an ABS slurry spread out on the heat-bed. It's just ABS plastic melted in acetone and then brushed on the heat bed.

Time, Lots of Time

Printing takes time. A lot of time. More time than I thought it would before I got my first printer. I've done prints that take over 10 hours to complete. When you print .3 millimeters layers out of a .4 millimeter hole, or some variation of those values, even medium size prints can take a long time. You can play with tons of different settings in your slicer program, specifically layer heights, for hours on end, but ultimately it's a balancing act. Some printer designs are built for speed better than others- both in stability and agility. The stepper motors can only go so fast. In the end, you have to find the optimum speed for your printer and the quality of prints you want. I've found that I wish it was faster, but I tend to like better prints instead of faster print times.

A Printer is Not All You Need to Print Something

Some have the idea that if something breaks around the house they'll just print a replacement. While this is technically feasible, the cost in terms of time is often prohibitive. The cost of materials, not so much. To print out some broken widget found around your house, you first need to get a 3D model of it or create one yourself. This requires both skill and time.

There are a growing number of websites out there that contain thousands of designs and models ready to be printed, and in the case of Thingiverse, to be customized and printed.